SOLUTIONS

Infrastructure Inspection &

Facility Assessment

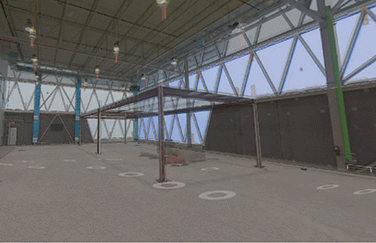

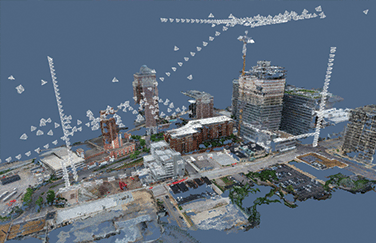

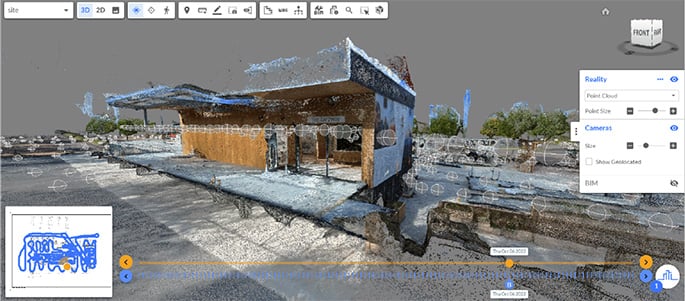

Whether assessing the current state of a building or capturing its progress from start to finish, Reconstruct transforms footage from 2D pictures, 360 cameras, drones, and more into an “online as-built”—a digital, mappable version of your construction project.

How It Works

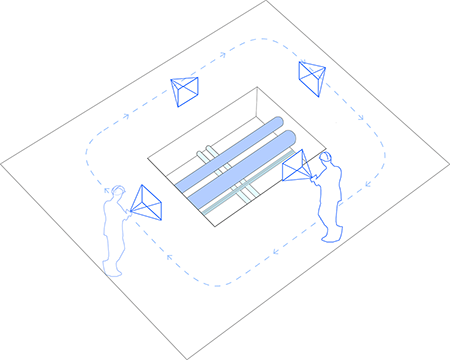

Capture your job site in its current state for a one-time archive, or record progress over time to create a timestamped visualization of construction progress from groundbreaking to project completion.

Stakeholders can use this online as-built to answer questions about what’s where, more efficiently facilitate maintenance and repairs, protect themselves against claims and litigation, and more.

Rapidly create an as-built digital twin of your job site.

Whether you have access to laser scanners or just a smartphone or 360 camera, Reconstruct can transform footage of your job site into a precise, measurable duplication of a building or structure. Perform reality capture once to generate an as-built record of your completed project, or record construction progress regularly to create a digital archive of the job site in space and over time.

Streamline maintenance, repairs, and operations.

Inspect infrastructure, examine a facility’s condition, rewind the clock to determine what’s where, and so much more—all without demolishing walls or even stepping foot on the job site.

Frequently Asked Questions

- How can infrastructure inspection software enhance the quality control process?

-

Infrastructure inspection software, which captures the reality of infrastructure using hardware such as smartphones, 360 cameras, drones, and laser scanners, empowers inspectors to view, measure, and refer back to the current and past conditions of infrastructure on demand, as planned, and over time—without the expense or distraction of travel.

This is especially true when inspectors are responsible for a vast portfolio of assets and job sites, and traveling to each one regularly would be impossible. Automated infrastructure inspection software won’t perform inspections for you but can produce a virtual duplication of the asset to be reviewed remotely. In other words, what's automated is the reality modeling—not the inspection. By creating a digital twin of the asset, stakeholders can get more eyes on the infrastructure—and intelligently dispatch in-person inspectors whenever necessary.

While some infrastructure construction inspections are required to be performed in person by a qualified inspector, utilizing the right reality mapping software enables stakeholders to supplement physical infrastructure and facility condition assessments with remote monitoring whenever possible, creating more transparency without exhausting budgets. - What criteria should I consider when choosing a cloud-based platform for facility condition assessments?

-

Commercial facility condition assessment software should accept and blend footage from all capture devices, including smartphones, 360 cameras, drones, Matterport scanners, and laser scanners. All data should be automatically integrated into a single source of project truth that’s as immersive and measurable as a physical walkthrough. Moreover, comprehensive facility condition assessment software should allow stakeholders to turn back time and inspect a facility’s condition at any moment in the past.

Building facility condition assessment software should also be easy enough to use so that members of a field team or other non-experts can capture reality data when necessary. While a laser scanner will always be reserved for professional use, empowering regular team members to capture reality regularly enables frequent, remote condition assessment.

- What are the benefits of remote inspection?

-

The chief benefits of remote infrastructure inspection—and facility assessment—are increased safety, reduced risk, increased efficiency, reduced costs, and improved historical accuracy. With the right remote infrastructure inspection tools, stakeholders can perform buildings and infrastructure inspections…

- without entering hard-to-read, extremely high, or otherwise unsafe areas, thanks to drone technology

- Inspect more facilities in less time with less travel, saving in-person inspection only when necessary or required by law.

- Spend less on professional site surveying and in-person inspection, reserving such budgets for when dispatching experts is truly essential.

- Maintain online, as-built documentation of the infrastructure, site, or facility that protects against future claims, answers questions about conditions over time, and more.

- What are the best tools for a remote site inspection?

-

Remote infrastructure inspection tools include reality mapping software and reality capture hardware. Reconstruct, for example, allows users to blend footage from virtually every type of device, including smartphones, 360 cameras, drones, Matterport scanners, and laser scanners. Footage is automatically blended into a virtual duplication (also known as a digital twin, 3D scan, or site survey) of the job site or the infrastructure, both in space and over time.

No floor plans or other documentation are required—instead, the photogrammetry engine uses cutting-edge technology and geo-referenced reality capture to recreate what you’ve captured.

Drones are perfect for exterior capture and high, hard-to-reach, or otherwise unsafe aspects of the job site. 360 cameras capture good, panoramic data of job sites very quickly. Smartphones are perfect for high-resolution snapshots of in-wall installations and other complex configurations. Laser scanning, which is expensive and much slower than other modes of capture, is often reserved for the final documentation of a job site.

- Can you automate a site inspection?

-

While a site inspection cannot be completely automated, Reconstruct’s reality mapping technology can make infrastructure construction inspection and surveying faster, more straightforward, and more affordable. By empowering remote stakeholders to review many sites in one sitting from one location, most inspections that may have been performed in person before can now be performed remotely and at scale, saving resources for the physical, on-site inspections that matter most.

- How does remote inspection improve safety for my field team and inspectors?

-

When an area or aspect of a job site inspection, such as infrastructure and utilities inspections and surveys, is too dangerous, hard-to-reach, or otherwise inaccessible, remote inspection can allow stakeholders to look closely at an asset’s concerns without the risk of bodily harm. Using reality mapping software, a drone or similar device can be piloted to capture current conditions, which are then reviewed carefully by experts.

- How do I balance on-site, physical inspection requirements with a remote inspection strategy?

-

There are many laws and regulations that require in-person, physical inspection of buildings and infrastructure. Reality mapping software was not meant to circumvent these regulations but instead assist stakeholders in keeping an eye on all projects in their purview between in-person inspections.

- How can remote inspection supplement required physical inspections?

-

Even when not required by law, remote site inspection, including buildings & infrastructure inspection, can help experts keep an eye on every project in their portfolio without constant travel, referring back to conditions over time to determine when a physical inspection has become critical. What’s more, if reality capture is conducted during physical inspection, inspectors and other stakeholders can review the digital twin for more information about a concern omitted from the original report.

Moreover, because reality capture can be performed by virtually anyone on the job site, regular field teams can gather the data for off-site experts, saving time and money while adding more and more data to the project’s digital twin over time.

Featured Articles

Remote Construction

Monitoring

Avoiding Costly

Rework

The Future of

Construction AI

Meet the companies that trust Reconstruct.

Burcin Kaplanoglu

Executive Director, Innovation Officer at Oracle Construction and Engineering