SOLUTIONS

Online As-Builts

With Reconstruct, creating a digital twin of a project as-built is effortless. At any time and from anywhere in the world, remote and on-site stakeholders can refer to these digital representations of any construction project, at any point along the construction timeline.

How It Works

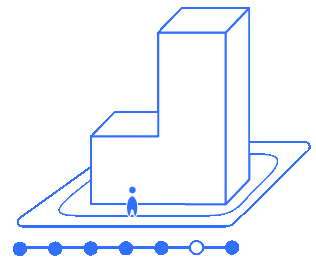

Reconstruct generates online as-built digital twins using its reality mapping technology.

These captures may be performed as a one-time facility assessment—or repeatedly over time to capture progress from groundbreaking to project completion.

Later, if and when necessary, these archives become data-rich resources during resolution, litigation, or handovers.

Online as-builts also reduce headaches and resource burn during maintenance or when determining what’s below, beneath, or above a floor, wall, or ceiling.

Remotely access an as-built digital twin of your structure.

Use any hardware to capture the reality of an in-progress or complete project, then watch as Reconstruct transforms the footage into a digital representation of the project. Footage can be captured once for facility assessment, or repeatedly throughout construction for an accurate, timestamped visualization of progress over time.

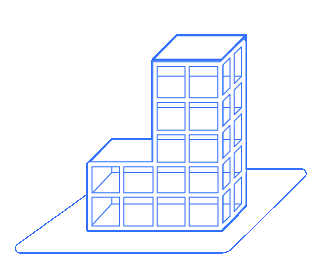

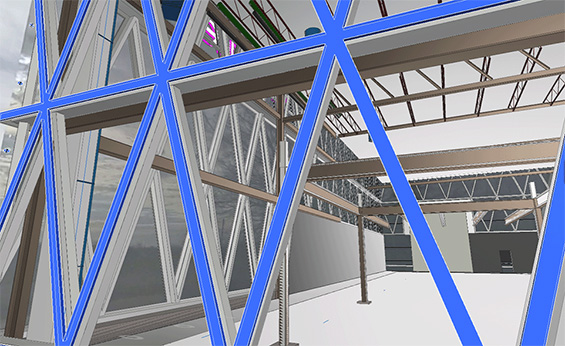

See through walls and protect against claims.

Reconstruct’s Visual Command Center gives you unprecedented remote access to every nook and cranny of a structure. Using as-built 3D models and 2D floor plans of your project, you can:

- Conduct thorough facility assessments.

- Look back in time to answer questions.

- Record existing conditions during handover.

- Optimize maintenance and operations.

- See through walls, underneath concrete, and above ceiling panels.

- Protect against litigation with timestamped archives of past work.

FREQUENTLY ASKED QUESTIONS

- What is the purpose of as-built drawings?

-

The purpose of as-built drawings (or as-built documentation) is to accurately represent a project's final, “as-built” state of construction. This documentation is typically referred to as as-built drawings, but it could also be a model, such as as-built BIM or an as-built digital twin generated via reality mapping technology.

As-built drawings can be used for various reasons, including future planning, understanding project details, or even answering liability claims.

- What is the difference between as-built drawings and design drawings?

-

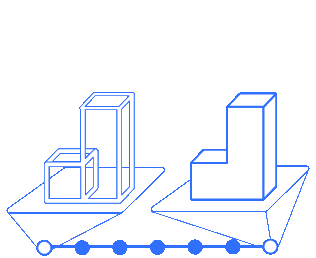

As-built drawings reflect a completed project's final physical measurements, whereas design drawings represent a project’s original intent. In other words, design drawings are plans: what architects and engineers imagined building before construction began.

In a perfect world, a project would be completed and match design drawings perfectly. This doesn’t usually happen, and it’s one critical reason why as-built drawings are so essential. For example, a single change order would be enough to render design drawings inaccurate. Only the final, as-built documentation would reflect this in-the-field change.

Further, as-built documentation using digital twins has revolutionized this process, providing accurate and comprehensive representations of built environments, often in less time and at a lower cost.

- Are as-built drawings accurate?

-

Whether as-built drawings are accurate depends on a variety of inputs. The first question: Do the as-builts show all the elements that exist in the field? For example, if you were to create an as-built drawing of the HVAC system or mechanical systems, and your surveyors forgot to include a ducting segment, then as-builts wouldn't be accurate. Stakeholders need to ensure that all of the elements built are actually on the drawing, as expected.

The second qualification for accuracy is: Do the drawings represent exactly where items exist in reality? The answer to this one isn’t so simple. It’s about how accurate stakeholders need their as-builts to be. Depending on that need, stakeholders can select the right tools, technologies, and teams to perform as-built documentation.

Another note: When an owner takes over a property, they may be supplied with as-built drawings. Assessing whether they are accurate is impossible without a reality survey, especially if the documentation is years old.

- What is required for as-built drawings?

-

As-built drawings require field verification. This means that someone needs to go to the physical construction site and capture all the necessary details to generate an as-built drawing.

Traditionally, this process would require surveying the site with photographs or hand sketches and taking measurements with a measurement tape or a laser measurement tool. Then, the details would be brought to a designer or engineer, who would be asked to draw the as-builts.

A more modern approach would be to do a reality capture of the site. And that could be with any one of the reality capture methods, whether 360 camera, drone, or laser scanning. That data could also be used as input to generate a BIM model or drawings. Now, the type of reality capture will kind of dictate the tolerances or the accuracy. So 360 capture will give you tolerances within, say, 1%. That means if you're measuring something that is 100 inches, it may be off by one inch.

Laser scanning would give you a tighter tolerance: accuracy within 1/16 of an inch.

- How much does an as-built drawing cost?

-

The cost of creating as-built documentation, including as-built digital twins, will vary greatly depending on your needs, project size, accuracy tolerances, desired mode of capture, and what experts (or technology) you tap to produce the drawings. For example, 360 capture is always going to be faster and less expensive than laser scanning. It’s all about choosing a tool that’s best for your project’s budget, timeline, requirements, and resources.

- How does an as-built drawing protect against liability?

-

Online as-built documentation can protect you from liability claims and other complaints and disputes. A few ways they offer protection include:

- Establishing when a change order is unnecessary.

- Resolving claims by proving who is responsible for what delays or additional costs.

- Demonstrating to a court when the quality of work did not meet contractual obligations.

You can learn more about these three protections in our article devoted to digital twins and liability protections.

Meet the companies that trust Reconstruct.

Burcin Kaplanoglu

Executive Director, Innovation Officer at Oracle Construction and Engineering